New Innovations

ICT, Electronics, and Security Technology

Coming Soon:

1. Vehicle Watch Guard

2. Alerts Recitor

3. Universal Doorbell CCTV Ringer

4. Unisex Shaving Mirror

CIVIL AND ENERGY SUSTAINABILITY INNOVATIONS

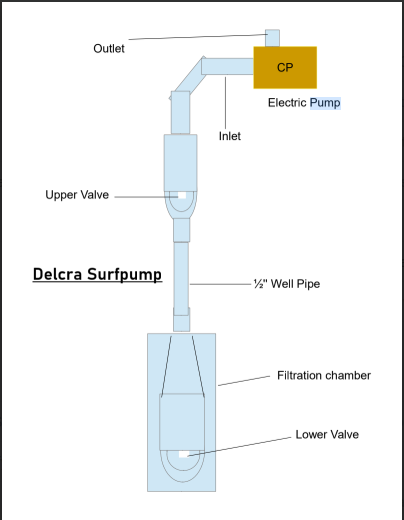

Delcra Surfpump: Water Delivery

Details

Details of the Delcra Surfpump System:

Delcra Surfpump was developed with the consideration of an efficient fluid pumping mechanism, adapting fluid capillarity to enhance water retention and maximize flow with less effort and virtually zero human intervention.

This is a surface-mounted pump system for deep wells; consisting of two valves, which are the “game-changers”, a filtration mechanism, and an electric pump (1 horsepower upwards). The system can deliver water supply or fluid from underground (a well of any depth) without the need for consistent priming and regular services for 10 years, using the two valves at specific points in the delivery system with pipe sizes that enhance fluid capillarity. The pump operates at surface level as compared to submerged pumps, where pumps are submerged into the water wells or fluid underground and hence require regular maintenance to keep them functional, and where the water may contain salt, which causes degradation,frequent power failure issues due to their exposure to the fluid in which they are submerged.

The Delcra Surfpump system has about 98% fluid retention due to a well-considered valve design acting as a one-way tight close and an easy open flap, guaranteeing constant fluid retention and flow at operation. The system therefore consists of

Underground Filtration System

Filtered Water Chamber

Underground/Lower valve( Sub-filter valve)

½” Pipe

Upper Valve

Electric Pump (1100watts or 1.5hp)/CP

- Underground Filtration System

Water in the well is filtered using a polyester woven membrane to prevent dirt from entering the chamber and clogging the valves.

- Filtered Water Chamber

The Sub-filter valve gets water from the filtered water chamber. It has a size of 2” in diameter and a height if 10”.

- Underground/Lower valve( Sub-filter valve)

The lower valve/Underground valve( Sub-filter valve) works like a foot valve, holding water with its one-way retention valve, and with the help of capillarity created by the narrow pipe deployed and vacuum created by the centrifuge pump at the surface, sends the water to the upper valve, which also retains it to make it easy for the surface pump to pull the water to the desired height. This one-way valve allows water to flow up but not downwards with tight closing but easy opening operation. The valve is kept in a filtration chamber to keep debris and foreign particles that might affect the valve from getting into the water being drawn. Water that gets into the valve rise up due to the vacuum created in the 1/2” tube above it.

- ½” Pipe

The pipe be can any size not higher than 0.5” to aid capillarity, but its length can be of any distance to the upper valve. The higher this pipe, the more horse power(hp) will be required from the pump. The pipe from the upper valve to the pump can be of any diameter, the big the better but not above 1.25” in diameter. This capillarity causes the water to get to the second valve, which is the upper valve.

- Upper Valve

The upper valve is another specially designed one-way valve, which is placed about 4ft below the ground surface in the well. The pipe from the upper valve to the electric pump can be of any distance. The upper valve also holds the water fully as the electric pump keeps creating the vacuum needed to draw the water out. Finally, the water gets to the pump inlet section with the priming slot well closed, it is centrifuged to the outlet to be delivered to a required height from ground level

- Centrifugal Electric Pump

The Centrifugal electric pump has a power of 1200watt, which is about 1.6hp. A 1hp pump is always capable of performing the required pumping but with reduce rate of delivery. Its impellers rotate to a create kinetic energy in the water. This moving energy in the water also creates a capillarity pressure in the pipe to the upper valve all the way to the lower valve. This is the ability which draws the water from the well, hence with the game-changers of the valves; ensuring that water is always kept in the pumping line, the system performs effortlessly. This same pressure pushes the water up to the required height.

Real World Trail of Delcra Surfpump.

This new system, innovated by Peter Delali Ivo of Delcra Phab, was been tried for 20 years in Adenta a suburb in Greater Accra Ghana, with a good flow rate and delivered to a tank height of 50 feet using a 1-horsepower pump from a well depth of 400 feet. The valves are not ordinary foot valves, which may cause consistent air gap problems due to less water retention, requiring continuous priming before water can flow to safeguard the pumps but are specially designed one-way valve with act as either completely closed or opened valve. The Delcra Surfpump system works effortlessly without any intervention due to its fluid retention of 98% and can be constructed to work automatically for wells and borehole water or other fluid deliveries. The efficiency of the fluid retention and low power demand make it highly recommended for solar-powered water delivery systems.

For Water delivery, the Delcra Surfpump system has a filtration of 20 microns and, at 400ft ground well can delivers 800 GPH to 50ft depending on the size of the delivery pipe size from the pump to the tank above ground. There is a Reverse Osmosis system also developed by Delcra, which can be added to this pump system to supply clean water for urban and rural communities.

The lower valve works like a foot valve but with high water retention capacity, which keeps filtered water in the well. This valve is kept in a filtration chamber to keep debris and foreign particles that might affect the valve from getting into the water being drawn. The valve allowing water to flow up but not downwards with tight closing but easy opening operation. Water that gets into the valve pipe gets to rise up due to the vacuum created in the tube above it caused by the pump at the surface, the pipe has a diameter of 0.5’’ (half an inch) to facilitate capillarity. This capacity causes the water to get to the second valve, which is the upper valve. The upper valve also holds the water fully as the electric pump keeps creating the vacuum needed to draw the water out. Finally, the water gets to the pump inlet section, which is centrifuge to the outlet for delivered to a height of 50ft from ground level. The upper valve is installed at 3 to 5 feet below ground level. The distance between the upper valve and the lower valve can be between 400ft, which was the well depth. The surface distance between the well and the position of the electric pump was about 50ft, before the water was pumped up to 50ft. To start the process the system is primed once; where water is filled to the upper valve by creating an inlet slot at the pump inlet side. Here the prime slot is closed tightly upon installation completion. With these metrics, a one-horsepower pump gave a flow rate of 800 GPH to 50ft.

Game-Changers:Main System Part

Subfilter Valve